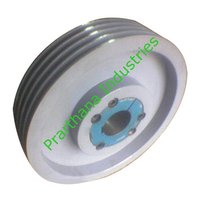

Taper Lock V Groove Pulley

Product Details:

- Diameter 150 mm (customized options available)

- Application Power Transmission, Industrial Machinery, Belt Drives

- Features Corrosion Resistant, Durable Construction, Easy Installation, Precision Balanced

- Bore Taper Bore (as per taper lock bush size)

- Mounting Type Taper Lock Bush Mounted

- Bearing Type Not Applicable (No Internal Bearing)

- Load Capacity Up to 3 tons (Varies by size and groove count)

- Click to View more

X

Taper Lock V Groove Pulley Price And Quantity

- Heavy Duty Box

- Diameter and groove options on request

- Black or As Per Requirement

- Standard SPA / SPB / SPC / SPZ (as per selection)

- 1210, 1610, 2517 (and others as per size)

- Up to 3600 RPM depending on bore

- -10°C to 60°C

- Machine Finished

Taper Lock V Groove Pulley Product Specifications

- Up to 3 tons (Varies by size and groove count)

- Power Transmission, Industrial Machinery, Belt Drives

- Not Applicable (No Internal Bearing)

- 150 mm (customized options available)

- Taper Lock Bush Mounted

- Taper Bore (as per taper lock bush size)

- V Groove Pulley

- Single / Double / Multiple Groove options

- Mechanical

- Corrosion Resistant, Durable Construction, Easy Installation, Precision Balanced

- Cast Iron

- Heavy Duty Box

- Diameter and groove options on request

- Black or As Per Requirement

- Standard SPA / SPB / SPC / SPZ (as per selection)

- 1210, 1610, 2517 (and others as per size)

- Up to 3600 RPM depending on bore

- -10°C to 60°C

- Machine Finished

Taper Lock V Groove Pulley Trade Information

- 10 , Per Day

- 15 Days

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

Taper Lock V Belt PulleyTaper Lock V Groove Pulley

Made from Cast Iron, Graded Cast Iron, S G Iron

"Z" Section, "A" section, "B" Section, "C" Section,"SPZ" Section, "SPA" section, "SPB" Section, "SPC" Section, "D" Section, "E" Section, "3V" Section, "5V" Section, "8V" Section.

70mm Outer Diameter to 2000mm Outer Diameter

22mm to 150mm Bore Range

1008 to 6050 Taper Lock Bush

Single Groove to Multiple Groove

As per Technical Specification or Drawing

Precision Engineered for Industrial Reliability

These V Groove Pulleys are constructed with high-grade cast iron and machine-finished surfaces to ensure consistent performance and a long service life. Designed for power transmission in diverse industrial machinery, they accommodate single or multiple groove configurations as per requirement, making them suitable for a wide range of belt drive applications.

Customizable Options to Fit Your Application

Customers can request specific diameters, groove counts, and surface finishes to precisely match their machinery needs. Each pulley is compatible with various taper lock bush sizes, providing flexibility during installation. Heavy-duty packaging ensures safe delivery and integrity of the pulley during transit.

FAQs of Taper Lock V Groove Pulley:

Q: How is the Taper Lock V Groove Pulley installed?

A: The pulley is mounted using a corresponding taper lock bush, such as 1210, 1610, or 2517, selected according to shaft size. This allows for swift, secure installation without the need for additional machining.Q: What are the primary applications for this pulley?

A: These pulleys are typically utilized in industrial machinery, power transmission systems, and belt-driven equipment where durability, high load capacity, and reliable performance are essential.Q: When should I choose a machine-finished surface pulley?

A: A machine-finished surface ensures improved belt grip, reduced wear, and consistent performance, making it ideal for applications demanding high precision and efficiency.Q: Where are these pulleys commonly used?

A: They are widely used in manufacturing facilities, processing plants, and any environment requiring robust power transmission solutions for mechanical drives.Q: What customization options are available for these pulleys?

A: Customers can request specific diameters, groove profiles (SPA, SPB, SPC, or SPZ), and custom color finishes to meet the unique demands of their applications.Q: How does the pulley benefit my industrial setup?

A: With precision balancing, corrosion resistance, and durable construction, this pulley enhances system efficiency, reduces downtime, and delivers long-term cost savings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese