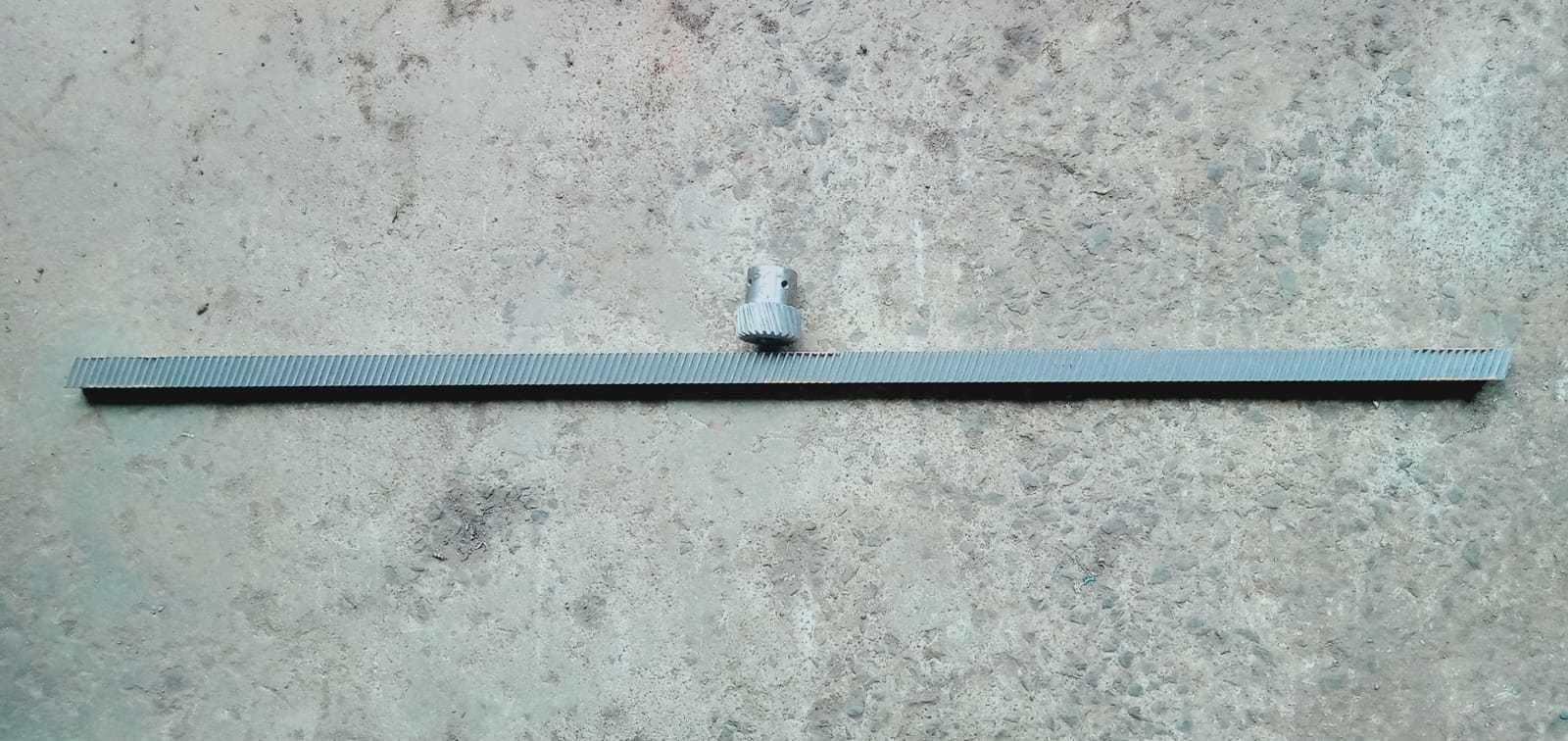

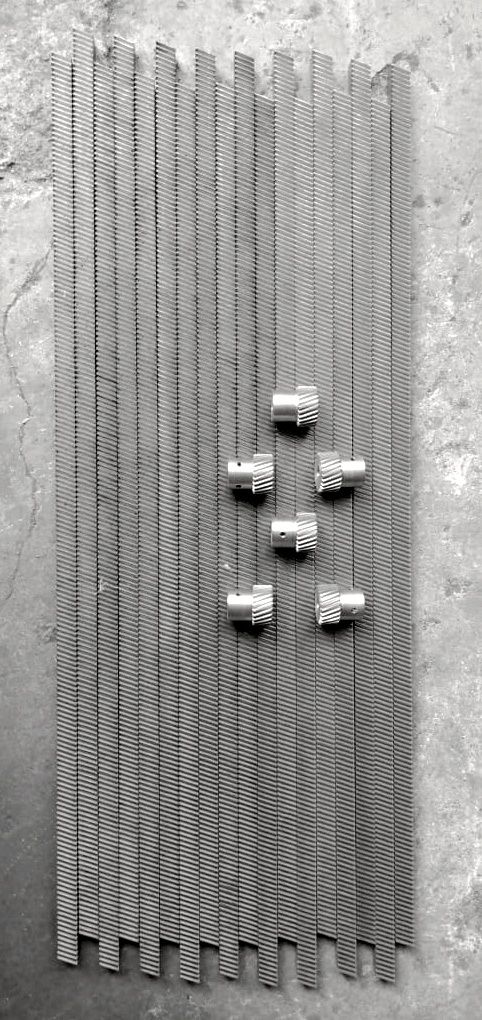

Helical Gear Rack

Product Details:

- Gear Type Helical Gear Rack

- Material Alloy Steel

- Processing Type Hobbing

- Gear Tooth Profile Helical

- Gearing Arrangement External

- Direction Right Hand

- Output Torque Customizable

- Click to View more

X

Helical Gear Rack Product Specifications

- Helical Gear Rack

- Up to 98%

- Helical

- Alloy Steel

- External

- Customizable

- Right Hand

- Hobbing

Helical Gear Rack Trade Information

- 15 Per Day

- 15 Days

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

Design: Standard or as per DrawingPitch: 01 Module to 06 Module

Surface Treatment: As Require

Length of Gear Racks: Up to 900

Teeth Profile : Helical Left or Right

Material : MS Bright Bar or as Require

Condition: New Only

Precision Engineering Meets Industrial Demands

Manufactured using premium alloy steel, our helical gear racks undergo precision hobbing to achieve consistent and durable gear tooth profiles. With tight tolerances of 0.05 mm and rigorous adherence to international standards (DIN, ISO, ANSI), these racks guarantee performance in CNC and industrial automation systems where reliability and accuracy are vital.

Optimized Performance and Versatility

Featuring ground or machined surface finishes and customizable output torque, these gear racks support efficiency levels of up to 98%. Right hand, external gearing arrangements facilitate smooth, quiet operation, especially when paired with recommended lubrication. Choose from a natural or blackodized finish to suit varied environmental and operational needs.

FAQ's of Helical Gear Rack:

Q: How are the helical gear racks processed to ensure durability and precise operation?

A: Our helical gear racks are produced using advanced hobbing techniques and are crafted from high-grade alloy steel. This results in superior gear tooth profiles with consistent hardness of 45-55 HRC, delivering reliable durability and smooth operation even in continuous industrial use.Q: What applications are ideal for these helical gear racks?

A: These racks are specifically designed for automation systems, CNC machinery, material handling equipment, and various industrial automation setups. Their precision, strength, and customizable output torque make them suitable for demanding environments needing accurate linear motion and high rigidity.Q: When should lubrication be applied to the gear racks for optimal efficiency?

A: Lubrication is recommended before commissioning the rack in your machinery and should be maintained regularly based on operating conditions. Proper lubrication minimizes wear, ensures a quieter operation, and helps maintain the rack's high-efficiency rating over time.Q: Where can these racks be utilized considering their modularity and length?

A: Given their customizable lengths up to 2000 mm and modules from M1 to M12, these helical gear racks are adaptable for both compact and large-scale applications in factories, automation lines, and CNC machines requiring precise linear movement and substantial load-bearing capacity.Q: What are the key benefits of choosing a ground or machined surface finish?

A: A ground surface finish delivers exceptional smoothness and accuracy, ideal for high-precision applications that demand minimal backlash. A machined finish provides reliable performance for standard industrial tasks, offering a balance between cost and functional accuracy.Q: How do standards like DIN, ISO, and ANSI contribute to the reliability of these gear racks?

A: Conformity to DIN, ISO, and ANSI standards ensures consistent quality, dimensional accuracy, and interchangeability, making maintenance and integration into international machinery straightforward and reliable for global operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese