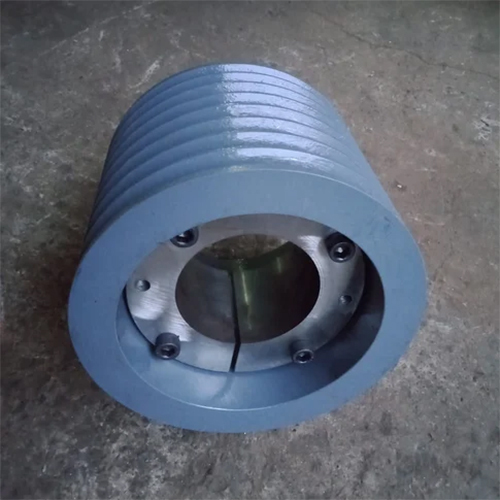

Taper Lock Timing Pulley

Product Details:

- Power Source Manual/Mechanical

- Mounting Type Taper Lock

- Application Mechanical Power Transmission

- Number Of Grooves Single or Multiple (as required)

- Bore Taper Bore

- Diameter Custom/Standard as per model

- Features High strength, Corrosion Resistant, Precision machined, Easy installation and removal

- Click to View more

X

Taper Lock Timing Pulley Product Specifications

- High strength, Corrosion Resistant, Precision machined, Easy installation and removal

- Mild Steel

- Mechanical Power Transmission

- Custom/Standard as per model

- Varies by size and type

- Taper Bore

- Single or Multiple (as required)

- Timing Pulley

- Manual/Mechanical

- Taper Lock

- Available for special requirements

- Smooth finish, rust resistant

- -20°C to 120°C

- Customizable as per design

- Phosphated or Blackodised

- Standard (HTD, STD, AT, or as specified)

- Boxed or as specified

- Available in various pitches per standard

- ISO/CE standard available

Taper Lock Timing Pulley Trade Information

- 15 Per Day

- 15 Days

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- All India

Product Description

Material : Aluminum , Mild Steel , Cast Iron , or as RequireProfile : 2mm to 20mm , T2.5 to T20 , MXL to XH

Diameter : 75mm to 900mm

with or without Flanges

With Taper Lock Bush 1008 to 6050

As per Drawing , Technical Data or Sample.

Superior Strength & Corrosion Resistance

Crafted from high-grade mild steel and finished with phosphating or blackodising, these timing pulleys provide excellent strength and enduring protection against corrosion. The outer surface is precision-machined to ensure a smooth finish, enhancing not only functional reliability but also facilitating easy maintenance and longer service life.

Versatile Customization for Diverse Applications

Every aspect of the Taper Lock Timing Pulley can be tailored, from the teeth profile and pitch to the number of grooves and diameter. This ensures seamless integration into various mechanical power transmission systems, regardless of design complexity or capacity requirements. Custom bore sizes and packaging further simplify logistics and installation.

FAQ's of Taper Lock Timing Pulley:

Q: How does the taper lock mechanism simplify the installation and removal of the timing pulley?

A: The taper lock design enables quick and accurate alignment on the shaft, allowing for easy mounting and secure fit. Removal is equally straightforward, reducing downtime during maintenance or replacement without causing shaft damage.Q: What are the main benefits of the phosphated or blackodised surface treatment?

A: Phosphated or blackodised treatments offer enhanced rust resistance and surface protection. This not only prolongs the lifespan of the pulley but also maintains its smooth operation in harsh environments, preventing premature wear or degradation.Q: When is it necessary to customize the number of teeth, pitch, or diameter?

A: Customization is advisable when your machinery or system requires specific torque transmission, speed ratios, or fits unique dimensional constraints. This ensures optimal power transmission efficiency and reliable performance in specialized applications.Q: Where can Taper Lock Timing Pulleys be used most effectively?

A: These pulleys are best suited for mechanical power transmission across various industries, such as manufacturing, packaging, and processing equipment, where precision, reliability, and modularity in drive systems are crucial.Q: What is the manufacturing process for ensuring high strength and precision in these pulleys?

A: The pulleys are manufactured using high-quality mild steel, undergo precise machining for perfect tooth profiling, and receive rigorous surface treatment for protection. Stringent QC checks ensure all components comply with ISO/CE standards, guaranteeing strength and reliability.Q: How does the smooth and rust-resistant finish benefit pulley usage?

A: A smooth, treated surface reduces friction and wear, improving operational longevity and reducing maintenance needs. Rust resistance ensures reliable function even in challenging or humid environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese