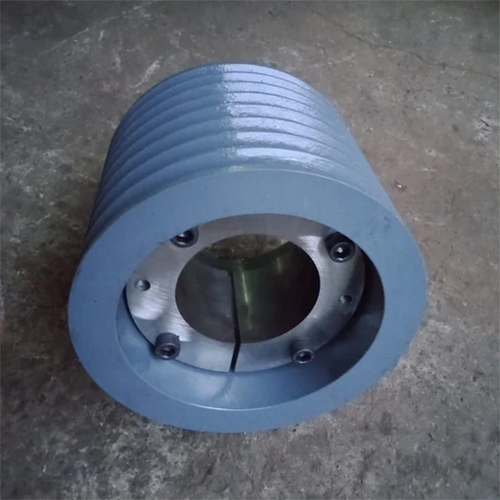

V Belt Pulley

Product Details:

- Mounting Type Fixed

- Power Source Manual/Mechanical Drive

- Bearing Type Without Bearing

- Pulley Type V Belt Pulley

- Application Mechanical Power Transmission, Industrial Machinery

- Bore Standard/Custom (based on requirement)

- Number Of Grooves 3 grooves (as shown in image)

- Click to View more

X

V Belt Pulley Product Specifications

- V Belt Pulley

- Mechanical Power Transmission, Industrial Machinery

- Standard/Custom (based on requirement)

- Cast Iron

- Depends on belt and system rating

- 3 grooves (as shown in image)

- Approx. 12 inch (refer image), customizable

- Manual/Mechanical Drive

- Fixed

- Without Bearing

- High Strength, Corrosion Resistant, Durable Finish

- Solid Hub

- Painted/Black Oxide

- Standard V groove 34° angle

- Static and dynamically balanced

- Estimated 5-10 kg, varies with size

- -20°C to +80°C

- Black or grey (as per manufacturer's supply)

- Low, periodic inspection recommended

- Precision machined grooves and bore

- A, B, or C Section (as per groove profile)

V Belt Pulley Trade Information

- 15 Per Day

- 15 Days

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- All India

Product Description

Cast Iron V Belt PulleyMade from Cast Iron, Graded Cast Iron, S G Iron

"Z" Section, "A" section, "B" Section, "C" Section,"SPZ" Section, "SPA" section, "SPB" Section, "SPC" Section, "D" Section, "E" Section, "3V" Section, "5V" Section, "8V" Section.

70mm Outer Diameter to 2000mm Outer Diameter

Single Groove to Multiple Groove

As per Technical Specification or Drawing

Precision Engineering for Reliable Performance

Each V Belt Pulley is crafted with solid hub construction and precision-machined grooves and bore, ensuring efficient belt grip and alignment. Whether used in mechanical power transmission or industrial machinery, its static and dynamic balancing minimizes vibration and enhances longevity, making it a preferred choice for demanding operations.

Customizable and Versatile Applications

The pulley accommodates A, B, or C section belt profiles and offers bore customization for varied shaft requirements. With a diameter of approximately 12 inches and three grooves, it integrates seamlessly into manual or mechanical drive setups, facilitating versatile usage across different industries in India and internationally.

FAQ's of V Belt Pulley:

Q: How is the V Belt Pulley installed and mounted onto machinery?

A: The V Belt Pulley uses a fixed mounting type and is designed for easy installation onto shafts. The bore can be standard or customized to fit specific requirements, ensuring secure attachment without bearings.Q: What belt sections are compatible with this pulley model?

A: This pulley is suitable for A, B, or C section belts, depending on the groove profile, allowing flexibility in usage across various mechanical power transmission systems.Q: When should the pulley be inspected for maintenance?

A: Periodic inspections are recommended to maintain optimal performance. Though the pulley requires low maintenance, checking groove wear and alignment during scheduled maintenance intervals is advisable.Q: Where is this V Belt Pulley commonly used?

A: The V Belt Pulley is widely utilized in industrial machinery and mechanical power transmission applications due to its robust design and compatibility with various belt sections.Q: What are the benefits of the painted or black oxide surface finish?

A: Both finishes offer strong corrosion resistance and a durable exterior, protecting the cast iron material from harsh environments and extending the pulley's service life.Q: How does precision machining affect pulley performance?

A: Precision machined grooves and bore guarantee accurate belt positioning and smooth operation, reducing vibration and enhancing the efficiency and longevity of the machinery.Q: Why is balancing important for this pulley?

A: Static and dynamic balancing ensures minimal vibration during operation, contributing to reliable performance and protecting adjacent machine components from unnecessary stress or premature wear.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese