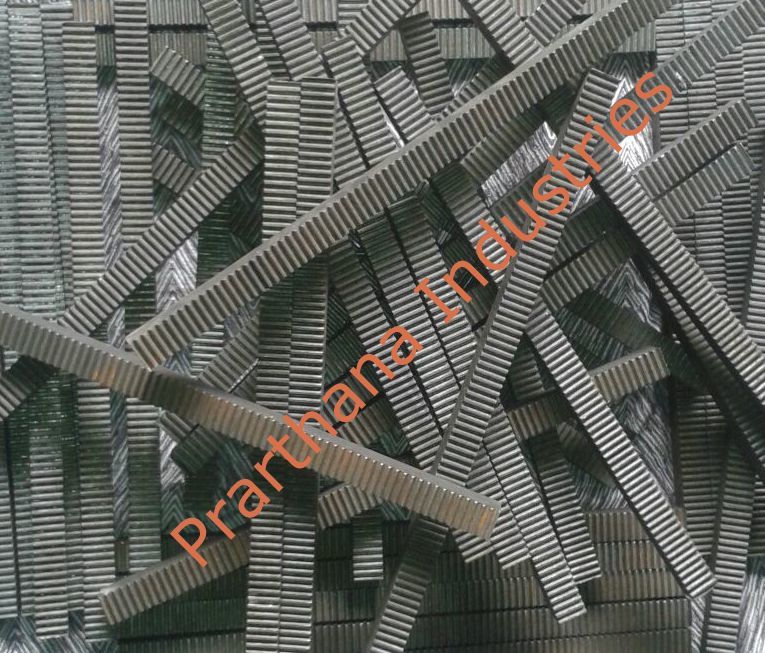

GEAR RACK

Product Details:

- Gear Type Rack

- Material Alloy Steel

- Processing Type Hobbing

- Gear Tooth Profile Spur

- Gearing Arrangement Rack and Pinion

- Direction Linear

- Output Torque Depends on Pinion and Application

- Click to View more

X

GEAR RACK Product Specifications

- Depends on Pinion and Application

- Hobbing

- Equivalent to Linear Velocity

- Alloy Steel

- Application Specific

- Linear

- Rack

- Rack and Pinion

- Dependent on Drive

- Up to 97%

- Spur

- Optional with plating or coatings

- DIN 69 (as per DIN standards)

- 10-25 mm (varies by model)

- Customizable (Standard: 1 meter)

- HRC 40-52

- CNC Machinery, Automation, Industrial Equipment

- -20C to +120C

- M1 to M6 available

- According to length and module

- Bolt-on

- Precision ground or milled

- 10-50 mm (varies by model)

GEAR RACK Trade Information

- 15 Per Day

- 15 Days

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia

- All India

Product Description

Design: Standard or as per DrawingPitch: 01 Module to 16 Module

Surface Treatment: As Require

Length of Gear Racks: Up to 3000mm

Teeth Profile : Spur or Helical

Material : MS Bright Bar or as Require

Condition: New Only

Customizable for Diverse Applications

Our gear racks are designed to suit a wide array of industrial requirements, from CNC machinery to automated systems. Clients can choose custom lengths, modules, and dimensions to match specific operational needs. The flexibility in material and finishing options further enhances adaptability, making these gear racks a practical solution for demanding environments.

Precision and Durability Assured

Manufactured from high-quality alloy steel and processed by hobbing, our racks are either precision ground or milled to adhere to DIN standards. With surface hardness rated HRC 40-52 and optional corrosion-resistant coatings, these racks ensure consistent performance and extended service life, even in challenging conditions.

Efficient and Reliable Linear Motion

Our rack and pinion arrangements guarantee linear movement with up to 97% efficiency. The bolt-on mounting method simplifies installation, while precise gear tooth profiles and DIN pitch accuracy improve mechanical stability. Engineered for reliable torque and speed transition, these racks support smooth automation and high-performance output.

FAQ's of GEAR RACK:

Q: How is the gear rack customized for different lengths and applications?

A: Gear racks are available in a standard length of 1 meter but can be customized according to client requirements. The module, width, and height are selected based on the specific application, ensuring optimal performance for CNC machinery, automation, or other industrial equipment.Q: What materials and finishing processes are used in these gear racks?

A: The gear racks are made from high-grade alloy steel, processed via hobbing, and finished with either precision grinding or milling. Optional plating or coatings enhance corrosion resistance, depending on application needs.Q: Where are these gear racks supplied and exported from?

A: We manufacture, supply, and export gear racks from India, serving a diverse range of industries both domestically and internationally.Q: What mounting method is utilized, and how is installation performed?

A: The gear racks use a bolt-on mounting system, which facilitates straightforward and secure installation onto CNC machinery and other industrial equipment. Precise alignment ensures reliable motion transfer.Q: When should corrosion-resistant options be selected for gear racks?

A: Corrosion-resistant plating or coatings should be chosen for gear racks if they will be used in environments exposed to moisture, chemicals, or other corrosive elements, thereby extending the lifespan of the product.Q: What is the significance of DIN pitch accuracy standards in gear racks?

A: Complying with DIN 6-9 pitch accuracy ensures high precision in tooth spacing, which is crucial for smooth linear motion, minimal backlash, and efficient power transmission in rack and pinion arrangements.Q: How does the gear rack contribute to improved efficiency and linear motion?

A: The gear rack's spur tooth profile and rack and pinion arrangement enable efficient conversion of rotary into linear motion, achieving up to 97% mechanical efficiency and reliable performance in various industrial automation systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese