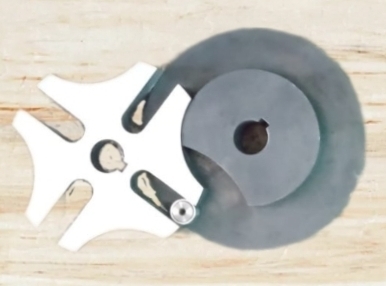

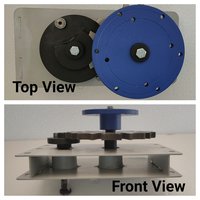

Geneva Mechanism

Product Details:

- Gear Type Geneva Wheel

- Material Alloy Steel / Stainless Steel

- Processing Type CNC Machined

- Gear Tooth Profile Involute

- Gearing Arrangement Fixed Axis / Intermittent

- Direction Bidirectional

- Output Torque 50-300 Nm

- Click to View more

X

Geneva Mechanism Product Specifications

- Up to 92%

- Fixed Axis / Intermittent

- Alloy Steel / Stainless Steel

- Involute

- 300-1800 RPM

- Bidirectional

- 0.5-2 kW

- Variable (Determined by Slot Number)

- 50-300 Nm

- CNC Machined

- Geneva Wheel

- 24 V / Custom

- Ground, Black Oxide / Phosphated

- Low

- -10°C to 80°C

- 800 kgf

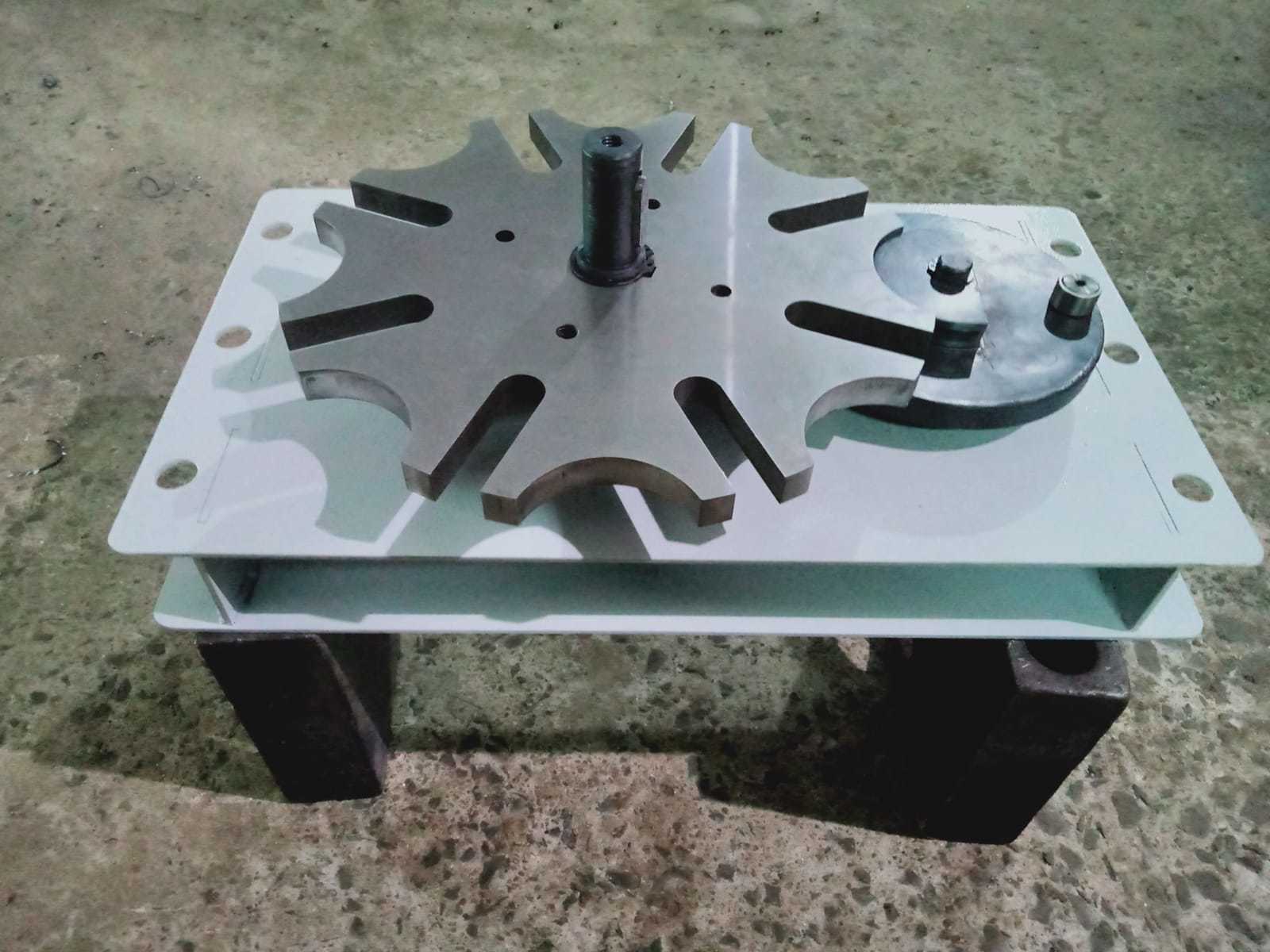

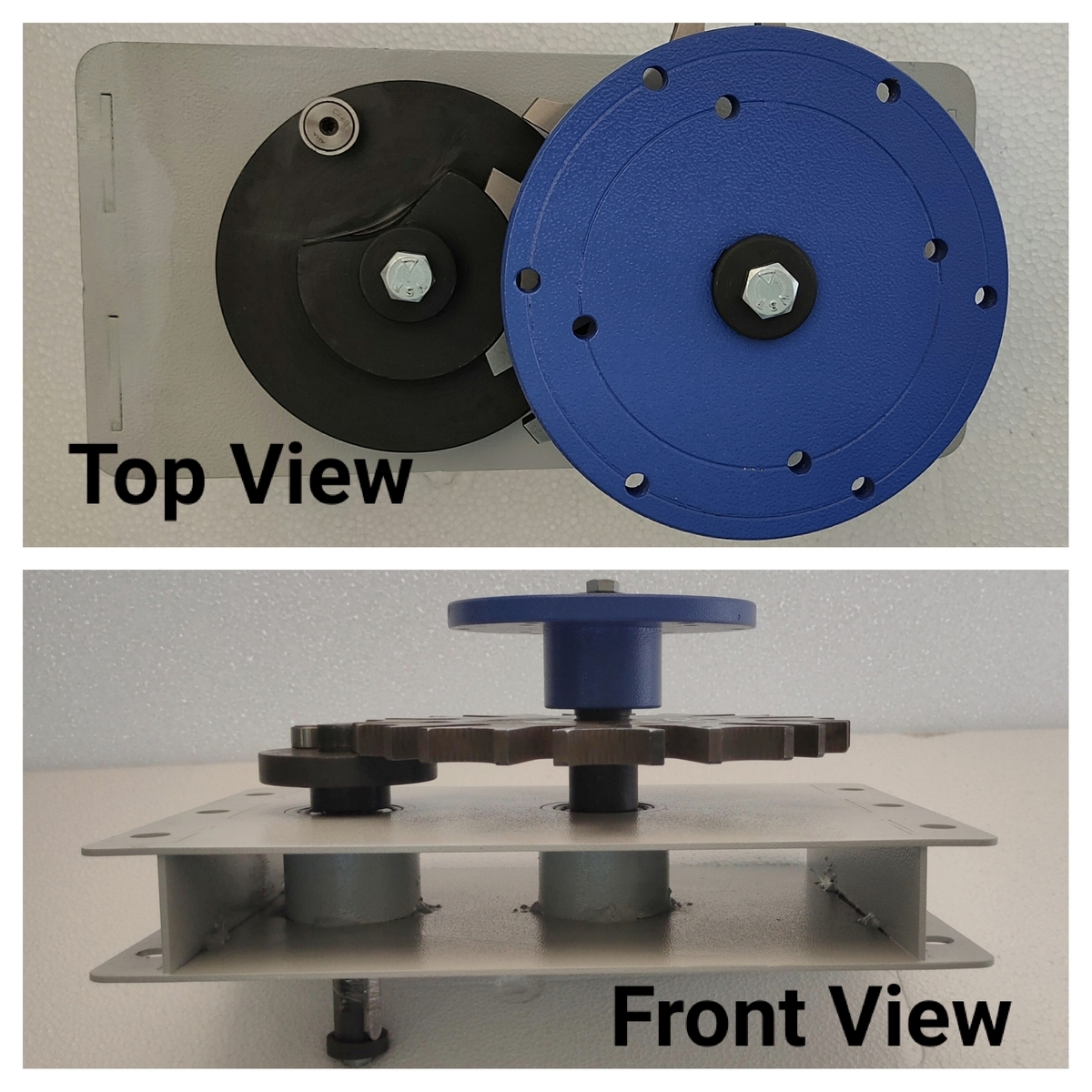

- Flange / Shaft Mounted

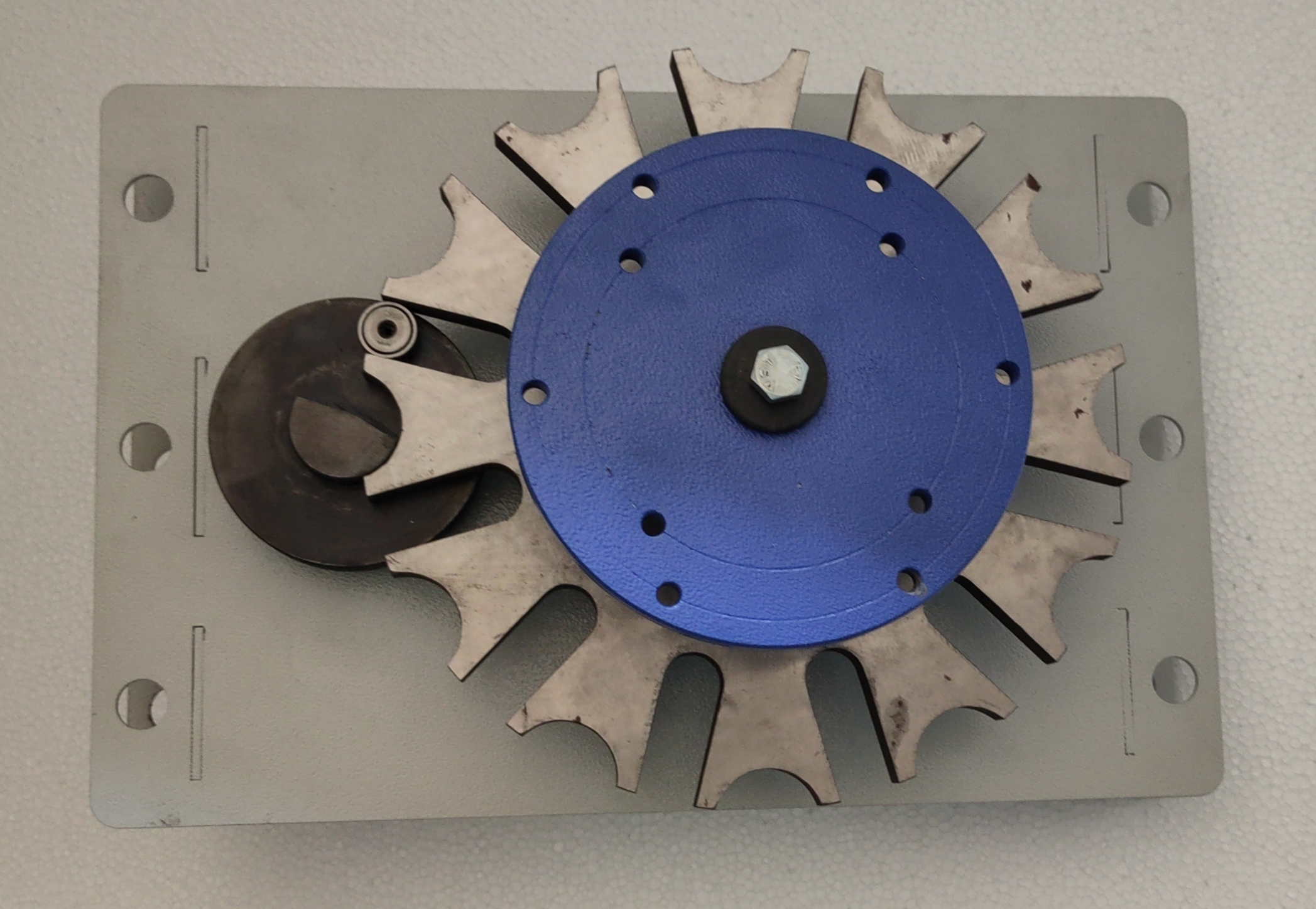

- 4-12

- Grease / Oil

- 30° to 90° (Customizable)

- Indexing, Packaging Machines, Automation Equipment

Geneva Mechanism Trade Information

- 1 Per Day

- 15 Days

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

- All India

Product Description

Geneva Drive, Geneva Wheel, Geneva Mechanismfor Indexing in Various Applications

Indexer Made from C-45/ En-9 Hardened and Ground

Ready Stock or Early Delivery for 4 - 6 - 8 - 12 Indexing Drives

Customizable to any Indexing with available input details.

Bottle filling - Capping , Cone/Cup Filling - Sealing, Tableting, Roti-Dosa Making.

Customizable Indexing for Automated Precision

The Geneva Mechanism offers a highly adaptable solution for indexing applications. With configurable slot numbers and stop angles, it enables precise control over motion intervals. Its fixed axis or intermittent gearing arrangement ensures reliable, repeatable operation, seamlessly integrating into a variety of automation and packaging lines. Robust construction and careful surface processing make it suitable for intensive use.

Durable Engineering and Versatile Configurations

Constructed from alloy or stainless steel and CNC machined for exceptional durability, the Geneva Mechanism maintains structural integrity even under heavy loads up to 800 kgf. Options for flange or shaft mounting allow flexible installation. Coupled with efficient lubrication, this system ensures minimal wear and consistently low operational noise, making it a sound investment for high-performance equipment.

Efficient Performance Across Diverse Conditions

Operating efficiently at input speeds up to 1800 RPM and delivering output torque between 50-300 Nm, the Geneva Mechanism serves a broad spectrum of industrial environments. With bidirectional capability and variable output speed determined by slot number, it offers dependable, low-maintenance performance amid fluctuating temperatures, contributing to streamlined automation and greater operational uptime.

FAQ's of Geneva Mechanism:

Q: How does the Geneva Mechanism achieve precise indexing in automation equipment?

A: The Geneva Mechanism uses a series of slots (4-12, customizable) and a driven pin to convert continuous motion into accurate intermittent rotation. This design allows precise control over indexing intervals, making it ideal for applications such as packaging machines and industrial automation.Q: What materials are used to manufacture the Geneva Mechanism and why are they chosen?

A: The mechanism is crafted from alloy steel or stainless steel. These materials are selected for their strength, wear resistance, and durability, ensuring reliable performance even under heavy loads and frequent cycling in demanding environments.Q: When should grease or oil lubrication be used for the Geneva Mechanism?

A: Lubrication type depends on operational speed, load, and environmental factors. Grease is preferred for slower speeds and sealed systems, while oil is best for high-speed applications or where continuous lubrication is desirable to reduce friction and support consistent low-noise operation.Q: Where is the Geneva Mechanism typically mounted within machinery setups?

A: It can be mounted using either flange or shaft mounting configurations. The choice depends on the machine layout and requirements, enabling flexible integration into diverse equipment such as indexing tables, conveyors, or packaging lines.Q: What is the process for determining the output speed of a Geneva Mechanism?

A: Output speed is influenced by the input speed and the number of stops (slots) in the mechanism. Fewer slots result in faster output rotation, while more slots provide slower, more frequent indexing. Customization allows matching the output motion to specific application needs.Q: What are the benefits of using a CNC machined Geneva Mechanism with an involute gear profile?

A: CNC machining ensures precise dimensions and optimal gear engagement with the involute profile, resulting in smooth transmission, high efficiency (up to 92%), and minimized operational noise. This translates to longer service life and consistent indexing accuracy.Q: How does low operational noise benefit automation and packaging applications?

A: Low noise levels contribute to a safer and more comfortable working environment, reduce risk of mechanical disturbances, and enable sensitive automation processes. This characteristic helps maintain productivity and ensures compliance with industrial noise standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese