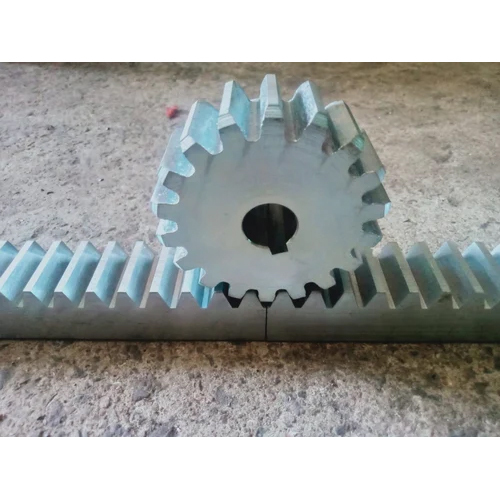

RACK AND PINION

Product Details:

- Gear Type Spur Gear, Rack Type

- Material Alloy Steel

- Processing Type Machined and Hardened

- Gear Tooth Profile Straight

- Gearing Arrangement Rack and Pinion

- Direction Bidirectional

- Output Torque Up to 2500 Nm

- Click to View more

X

RACK AND PINION Product Specifications

- Up to 2000 rpm

- Varies as per application

- Up to 2500 Nm

- N/A (Mechanical Component)

- Machined and Hardened

- Spur Gear, Rack Type

- Alloy Steel

- Straight

- Up to 98%

- Synchronizes with driving pinion

- Bidirectional

- Rack and Pinion

RACK AND PINION Trade Information

- 15 Per Day

- 15 Days

- South America, Middle East, Africa, Central America, Eastern Europe, Western Europe, Asia, North America, Australia

- All India

Product Description

Design: Standard or as per DrawingPitch: 01 Module to 16 Module

Surface Treatment: As Require

Length of Gear Racks: Up to 3000mm

Teeth Profile : Spur or Helical

Material : MS Bright Bar or as Require

Precision Engineering for Demanding Applications

Designed for robust industrial, automotive, and automation requirements, our rack and pinion solutions offer superior accuracy and torque handling. Each component is crafted from hardened alloy or high carbon steel, ensuring high durability and minimal backlash during operation. The customizable design allows seamless integration into both new and retrofit systems.

Customization to Suit Your Needs

Whether you need special dimensions, finishes, or tooth profiles, our rack and pinion systems are tailored as per your drawing or sample. The versatility in module range (M1 to M10), rack length, and mounting options enables application-specific solutions for diverse operational challenges across multiple industries.

Surface Treatments and Corrosion Resistance

Choose from phosphated, ground, or black finishes to ensure optimal surface protection and aesthetic appeal. For harsh environments or outdoor applications, corrosion-resistant treatments are available on request, enhancing the longevity and reliability of each gearset.

FAQ's of RACK AND PINION:

Q: How is the rack and pinion system customized according to specific requirements?

A: We offer full customization based on your drawings or samples, including rack length, module size (M1-M10), number of pinion teeth, mounting configuration, and surface treatments. This ensures perfect compatibility with your application needs.Q: What process is used for manufacturing and finishing the racks and pinions?

A: Both racks and pinions undergo precision machining and hardening for strength and durability. Surface treatments such as phosphating, grinding, or black finishing are applied to improve appearance and wear resistance. Corrosion-resistant options are available whenever required.Q: Where can rack and pinion systems be used?

A: These systems are ideal for automotive, industrial automation, and general machinery, especially where accurate linear motion and bidirectional control are needed. They suit a variety of motion transmission tasks with synchronized and reliable performance.Q: What are the key benefits of using these rack and pinion systems?

A: They provide exceptional pitch accuracy of 0.05 mm, high efficiency up to 98%, and robust construction for prolonged operational life. Their customizable features and resistance to wear and corrosion make them suitable for demanding environments.Q: When should corrosion-resistant rack and pinion systems be considered?

A: Corrosion-resistant variants are recommended for applications exposed to moisture, chemicals, or outdoor environments. Request this treatment if your operating conditions threaten standard finishes or extended product longevity.Q: How is the rack and pinion lubricated for optimal performance?

A: They are grease-lubricated by default, ensuring smooth motion, reduced wear, and a long service interval. Proper lubrication is essential, especially in high-speed or high-load applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese